HIGH SPEED AND PRECISION

High Performance Beyond Ordinary Injection System

Why choose us

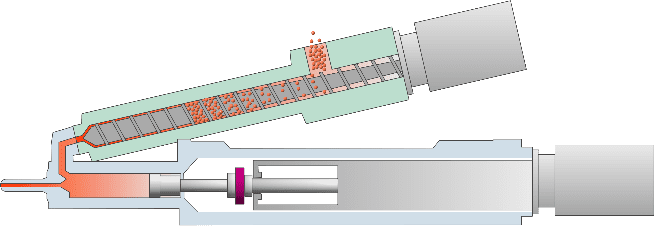

REAL series full electric two-stage plunger system was design based on this four principles, the system achiveves perfect harmony of critical plasticizing and injection functions. The two-stage plunger system has ability of total beyond the normal injection system includs injeciton speed , injeciton precision and shotting stability.

Advantages

Constant barrel heating profile

Constant material viscosit

Constant of precision filling volume

Precise holding pressure

Precise injection position

Complies with CE and UL standards

REAL series full electric two-stage plunger system provides 16-40mm plasticizing screw and 8-40mm injection plunger. The injection shotting weights offset up to 0.001g, the max. injection pressure up to 3500Bar and the injection speed 500-1300mm/s.