FULL ELECTRIC INJECTION SYSTEM

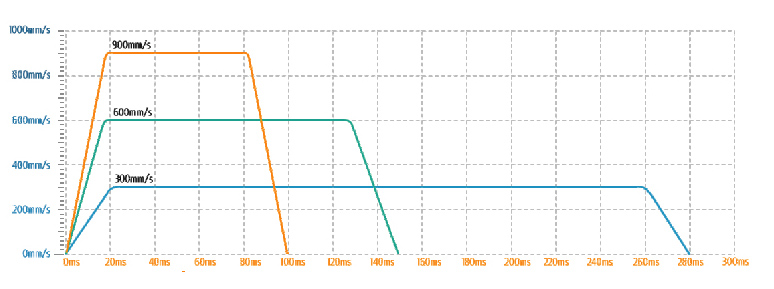

Real series machine has super high reproducibility and precision of movements thanks to the high-speed cpu and real-time field bus system.

Stability

The extreme motion control technology and servo system, make injection resolution up to 0.01mm,weight offset less then 0.01g.

Swiss made Loadcell and High dynamic injection unit with optimization pressure close loop algorithm.High grade electric and pneumatic parts, Strengthening mechanical structure, make higher production quality.

Economy

Advanced intelligent servo driver system, low loss mechanical structure, optimization barrelheating and designed machine Heat dissipation structure.

Fully servo motor drive directly, without inertia and without oil as medium, power consumption down to 0. 3kwh/ kg.

High dynamic and precision injection movements, less product weight over 6% as conventional hydraulic machine.

Long life time

Intelligent mold protection, reduce the risk of mold crush.

Close loop trajectory of axis movements, reduce mechanical wear.

Close loop torque control, protect mold and reduce loss.

Capacitive touch screen, Ultra long life time.

Clean

All driven by servo motor, no hydraulic components and oil.

Japan import ball screw and linear guides ensure the long life and clean.

Industry standards LUBE professional lubrication system.

Productivity

Machine equipped compress injection, ejector during mold opening and some other parallel movements. may effectively shorten the cycle time.

ree programmable process sequence representation of any production process.High speed servo motor and optimized system design for extremely short cycle times and maximum productivity duo to the consistent quality of parts.

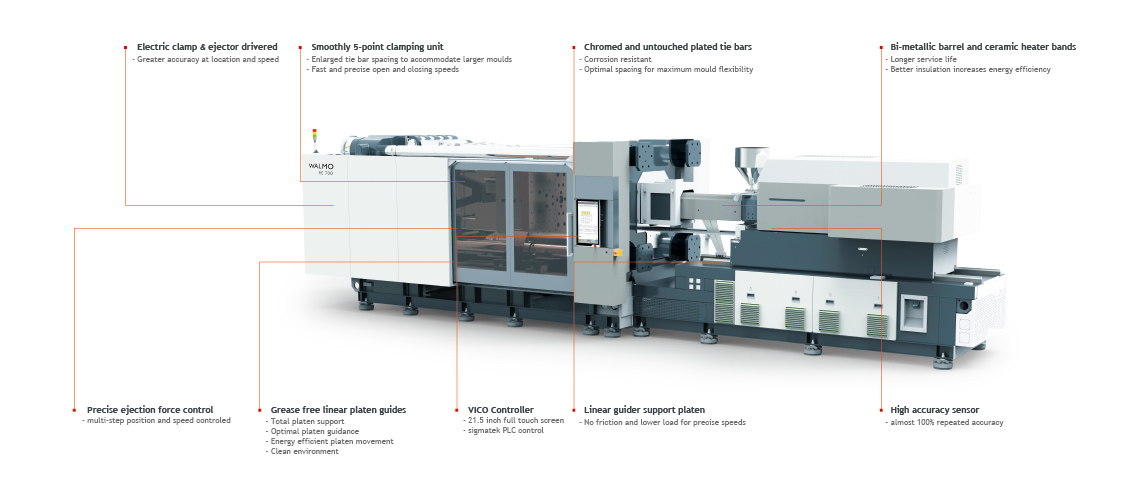

Large tie-bar space, long ejector range, comply Chinese standard and Europe standard mold plate, save a lot production preparation time.

Innovation

Continue study the latest technology of control and motion, investment in a large number of R&D costs to has a wealth of technical reserves.Searching for the latest industry information and process features, challenge the new molding requirements.

Continue developing information technology and integration technology.